Keyway Broaching for Elevators

Elevators are integral to modern vertical transportation systems, facilitating the movement of people and goods in buildings of all sizes. Precision engineering of elevator components is crucial for ensuring smooth operation, reliability, and, most importantly, safety. Keyway broaching offers a specialized machining solution tailored to meet the unique demands of elevator manufacturing.

Understanding Keyway Broaching:

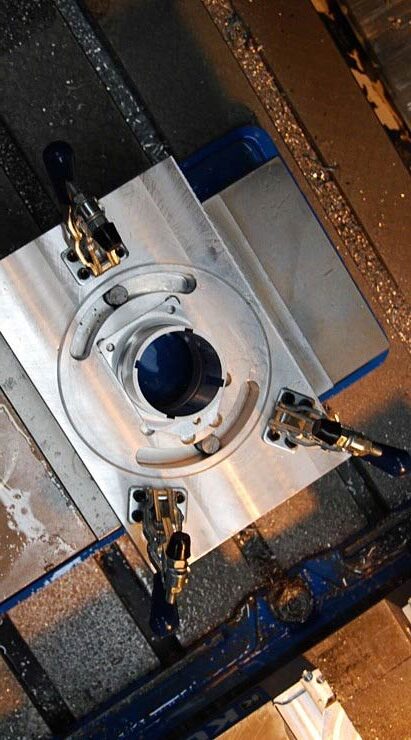

Keyway broaching is a machining process designed to create precise keyways – slots or grooves – in components, facilitating the secure attachment of gears, pulleys, or other mechanisms. In the context of elevators, keyway broaching enables the precise fitting of critical components such as drive shafts, pulleys, and gear assemblies, ensuring efficient and reliable operation.

Importance of Precision in Elevator Manufacturing:

Elevators operate in dynamic environments where safety and reliability are paramount. Precision manufacturing of elevator components is essential to ensure smooth rides, minimal downtime, and compliance with stringent safety regulations. Keyway broaching allows manufacturers to achieve the tight tolerances required for seamless operation and long-term performance.

Benefits of Keyway Broaching for Elevators:

Precise Component Alignment: Keyway broaching ensures precise alignment between key components, such as drive shafts and gears, minimizing wear and reducing the risk of mechanical failure.

Enhanced Strength and Durability: By creating uniform keyways, keyway broaching enhances the structural integrity of elevator components, improving their ability to withstand heavy loads and repetitive use.

Optimized Performance: Precisely machined keyways reduce friction and ensure smooth operation, enhancing the overall efficiency and performance of elevator systems.

Tailored Solutions for Elevator Applications:

Our state-of-the-art equipment and experienced machinists ensure the precise machining of keyways in elevator components, guaranteeing optimal performance, reliability, and safety.